A groundbreaking initiative underway in Europe seeks to develop a battery that’s not only efficient but also environmentally sustainable. Researchers involved in this project are claiming to have created a remarkable “super glue” that can maintain the integrity of the battery pack even when it sustains damage. This innovative chemistry incorporates unique cathodes and anodes paired with a novel electrolyte designed to protect both components during operation.

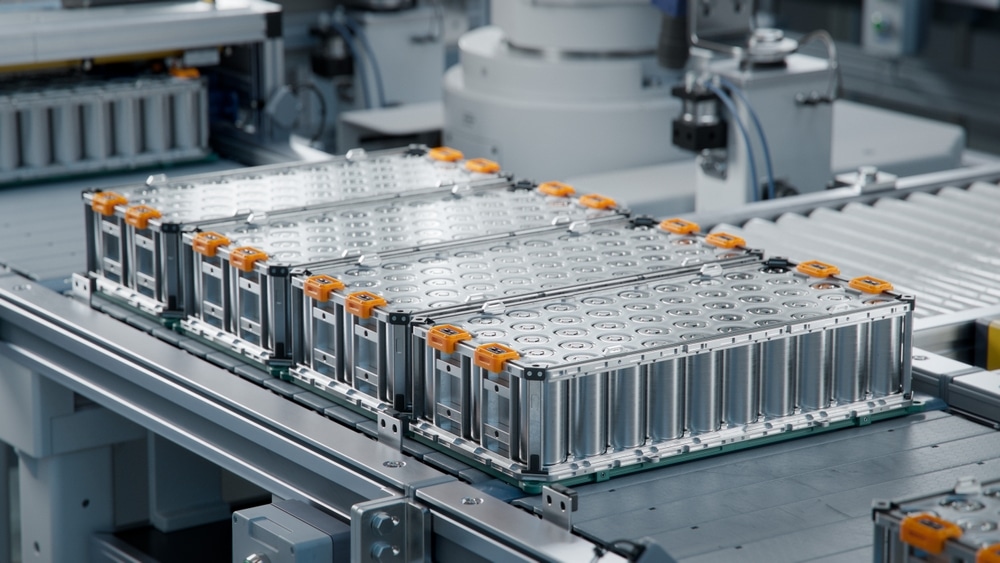

When it comes to electric vehicle (EV) batteries, there’s no one-size-fits-all answer. Different vehicle categories feature varying battery sizes, and their chemical compositions can greatly differ. However, what remains constant among battery manufacturers is a shared goal: to achieve higher energy density, faster charging times, cost efficiency, and improved safety. As the quest for these advancements evolves, scientists and engineers are exploring alternatives, one of which is the concept of a “self-repairing” battery pack that aligns with environmental standards.

A Norwegian research organization, SINTEF—known as The Foundation for Industrial and Technical Research—has been testing a revolutionary battery design that claims to be more stable than the traditional lithium-ion packs currently dominating the market. This new design promises enhanced driving range and a longer lifespan. SINTEF likens their battery to a “sandwich,” with the cathode on top, anode at the bottom, and dynamic separators and binders in between. While the sandwich analogy applies broadly to batteries, what sets this design apart is its innovative dual-material approach.

At the core of the battery, the cathode employs lithium-nickel-manganese oxide, which notably eliminates the use of cobalt and reduces the reliance on nickel and lithium compared to conventional EV batteries. This thoughtful chemistry yields a higher average voltage—a significant boon for both charging speed and overall performance. In layman’s terms, this means more energy stored in a more compact package, as highlighted by SINTEF scientist Nils Peter Wagner in an interview with British publication Tech Xplore.

Turning to the anode, a silicon-graphite composite forms the backbone of this battery innovation. Many American battery companies, such as Amprius, Group14, and Sila Nanotechnologies, are exploring silicon-based anodes, which address inefficiencies commonly found in graphite-heavy designs. While silicon does have the drawback of swelling during charge and discharge cycles, incorporating a graphite composite enhances its strength and stability, thereby overcoming this challenge.

What’s even more fascinating is the battery’s incorporation of a “super glue” feature, which helps to mend minor damage to the cells—similar to how a self-sealing tire works. This design includes special binders and separators that ensure the battery’s structural integrity is maintained. To simplify, think of a binder as the glue that holds together the active particles within the battery, while a separator acts as a protective barrier, preventing short circuits by keeping the cathode and anode apart. According to SINTEF, the first-generation prototype of the electrolyte utilizing these materials has been successfully developed, and efforts are now concentrated on crafting second-generation cells.

The significant step ahead in this project involves transitioning from laboratory innovation to market applicability. Reports suggest that plans are in motion to scale up production. While it’s exciting to design groundbreaking technologies in a lab setting, the real challenge is transforming those ideas into a product that can be manufactured at scale. The landscape is dotted with numerous battery chemistry advancements we’ve seen over recent years; however, far fewer have made their way into practical use.

Bob Lee, president and chief strategy officer of LG Energy Solution in North America, emphasized this point during a conversation on the Autoline Network podcast, stating, “Manufacturing is the technology. Trying to produce [batteries] in high volumes across large surface areas in a uniform way—that is the trick.” This insight underscores the complexities of taking a promising scientific innovation and making it accessible to drivers around the world, an endeavor many in the industry are eager to tackle.

If you have insights or tips relevant to this topic, I invite you to reach out. Your contributions can help in sharing vital information as we collectively navigate the exciting yet challenging world of EV battery development.

Image Source: IM Imagery / Shutterstock